JobQ Manager – Beyond Manual Tracking, Into Process Twins

Most shop floors still rely on paper, whiteboards, or disconnected ERP terminals to track manual operations. While these methods capture activity at a station, they fail to reflect the reality of how jobs actually flow across your production line.Manufacturing efficiency often relies on seamlessly connecting diverse technologies—from manual assembly lines to robotic automation and enterprise databases. JobQ Manager bridges these critical gaps, acting as powerful middleware to integrate, streamline, and optimize your production operations.

JobQ Manager changes that.

Unlike single-station operator tools, JobQ Manager acts as a process-level digital twin, giving you visibility across jobs, operators, and stations—not just one workstation. By integrating operator input, machine data, ERP work orders, and quality events, JobQ Manager builds a living model of your production process.

What You Can Do with JobQ Manager:

- Track job flow in real time across multiple stations and lines.

- Eliminate whiteboards and manual WIP tracking with dynamic queues.

- Identify bottlenecks early before they disrupt throughput.

- Push prescriptive instructions back to operators and supervisors.

Middleware Advantage

As middleware, JobQ Manager connects disparate systems—operator HMIs, ERP, MES, PLCs, and quality tools—into one unified view. This transforms siloed data into structured, actionable intelligence for decision-making.

The Result

Where others stop at asset monitoring, JobQ Manager delivers a true process digital twin: a synchronized, predictive, and prescriptive model of how your shop floor really works.

Why JobQ Manager Is Essential for Your Manufacturing Environment:

1. Unified Visibility and Control

JobQ Manager addresses a significant manufacturing challenge—the lack of real-time visibility into both manual and automated assembly lines. By connecting disparate systems, JobQ Manager ensures operators and managers have a clear, centralized view of production progress, enabling proactive decisions and reducing downtime.

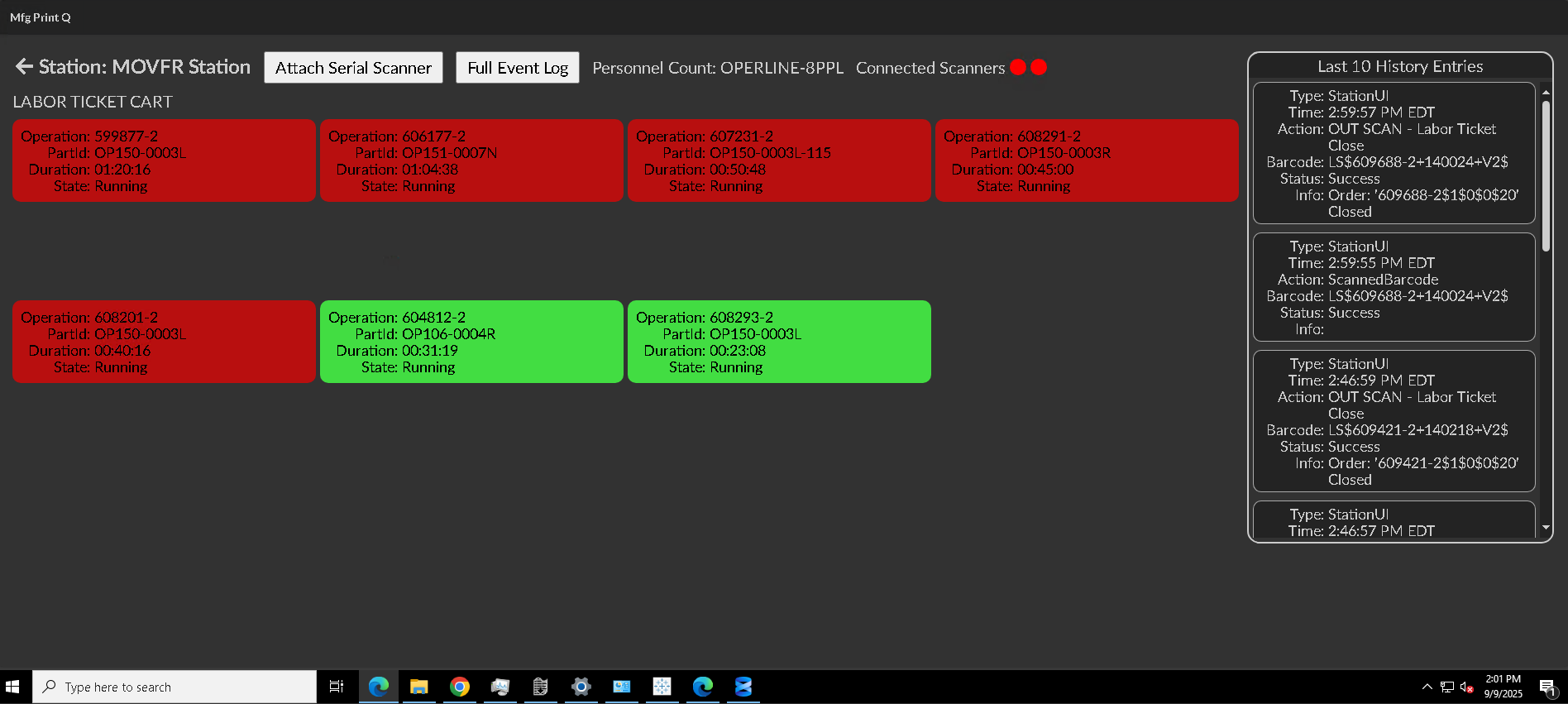

2. Intelligent Barcode & RFID Scanning

Acting as a skilled traffic controller, JobQ Manager harnesses barcode and RFID scanning to quickly identify, route, and manage parts and work orders. Each scan seamlessly triggers precise actions and workflows, dramatically reducing errors and delays, and maintaining accuracy across your production environment.

3. Specialized Manufacturing Middleware

Robotic automation often speaks unique, complex languages not recognized by standard business software. JobQ Manager expertly translates this specialized "robot language" into meaningful data for your ERP, MES, and analytics systems, enhancing overall system interoperability and workflow efficiency.

4. Automated and Serialized Printing

JobQ Manager integrates advanced printing capabilities directly tied to your SQL databases. Automatically generate serialized labels, identification tags, and comprehensive print records. This automation enhances compliance, ensures accurate traceability, and significantly streamlines your printing processes.

5. Custom HMI Deployment for Enhanced Manual Workflows

Recognizing the importance of intuitive interfaces for operators, JobQ Manager enables the deployment of customized Human-Machine Interfaces (HMI). These tailored HMIs simplify interactions, enhance manual workflow efficiency, and provide operators with direct, user-friendly control over complex manufacturing processes. JobQ Manager support reason codes to identify root cause for production impact.

6. Flexible Integration via Web API

Utilizing powerful Web APIs, JobQ Manager integrates effortlessly with existing ERP, MES, custom software, and cloud-based systems. This flexibility ensures rapid data exchange and seamless connectivity, future-proofing your manufacturing operations.

Flexible and Scalable Middleware Solution:

Built for scalability, JobQ Manager’s straightforward licensing model and ease of integration make it ideal for growing operations. Whether managing manual assembly stations, robotic automation, or mixed production environments, JobQ Manager provides a practical, cost-effective solution tailored to your specific needs.

Elevate Your Manufacturing Efficiency:

- Connect and unify disparate manufacturing systems.

- Gain real-time visibility into manual and robotic operations.

- Automate barcode, RFID, and serialized printing workflows.

- Deploy custom HMIs for streamlined manual task execution.

- Bridge robotic and traditional software languages seamlessly.

Choose JobQ Manager—Connecting Systems, Streamlining Processes, Driving Manufacturing Excellence.

See a Job Q Manager Success Story!