Know what’s happening.

Prove what was done.

Prevent what can’t happen.

TSRB Production Intelligence is an operational intelligence layer for discrete manufacturing—built to turn machine, quality, and flow signals into real-time visibility and governed execution. It’s not a KPI wallboard. It’s a system that drives action.

Capabilities

Production intelligence that operators can’t ignore

TSRB PI focuses on the moments that decide whether you ship on time: downtime, quality holds, readiness failures, constraint protection, and recovery actions. When something matters, the system makes it visible—and makes it executable.

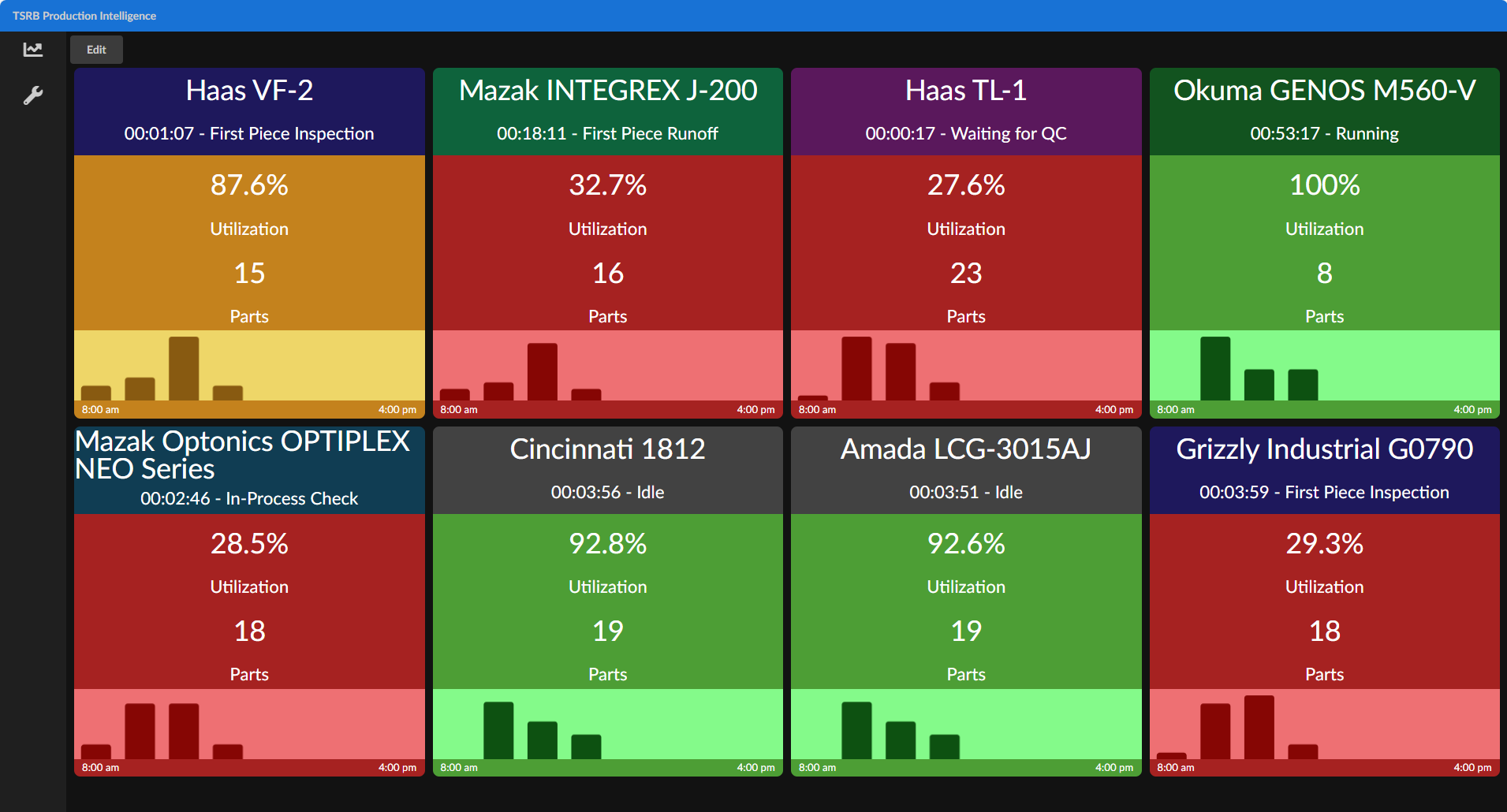

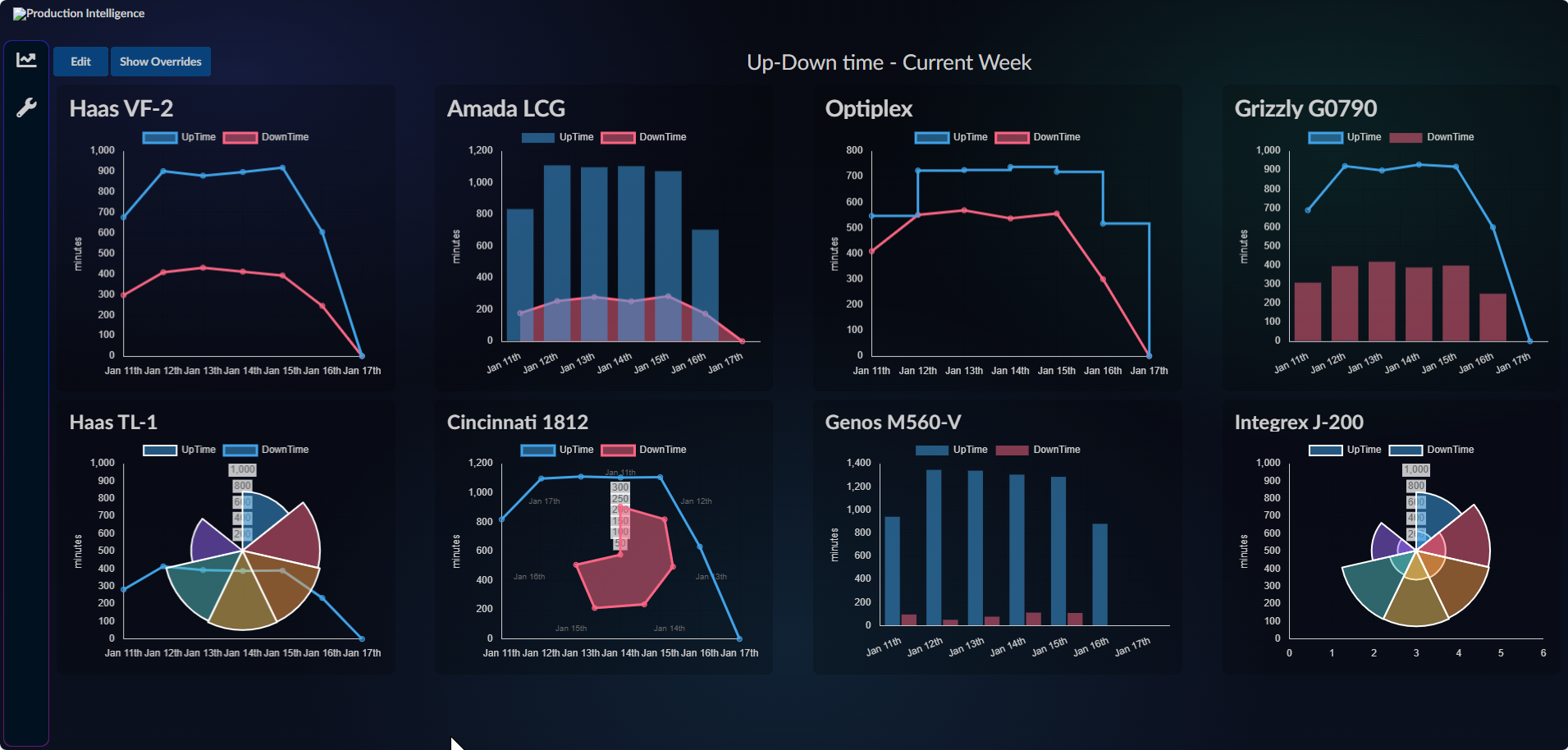

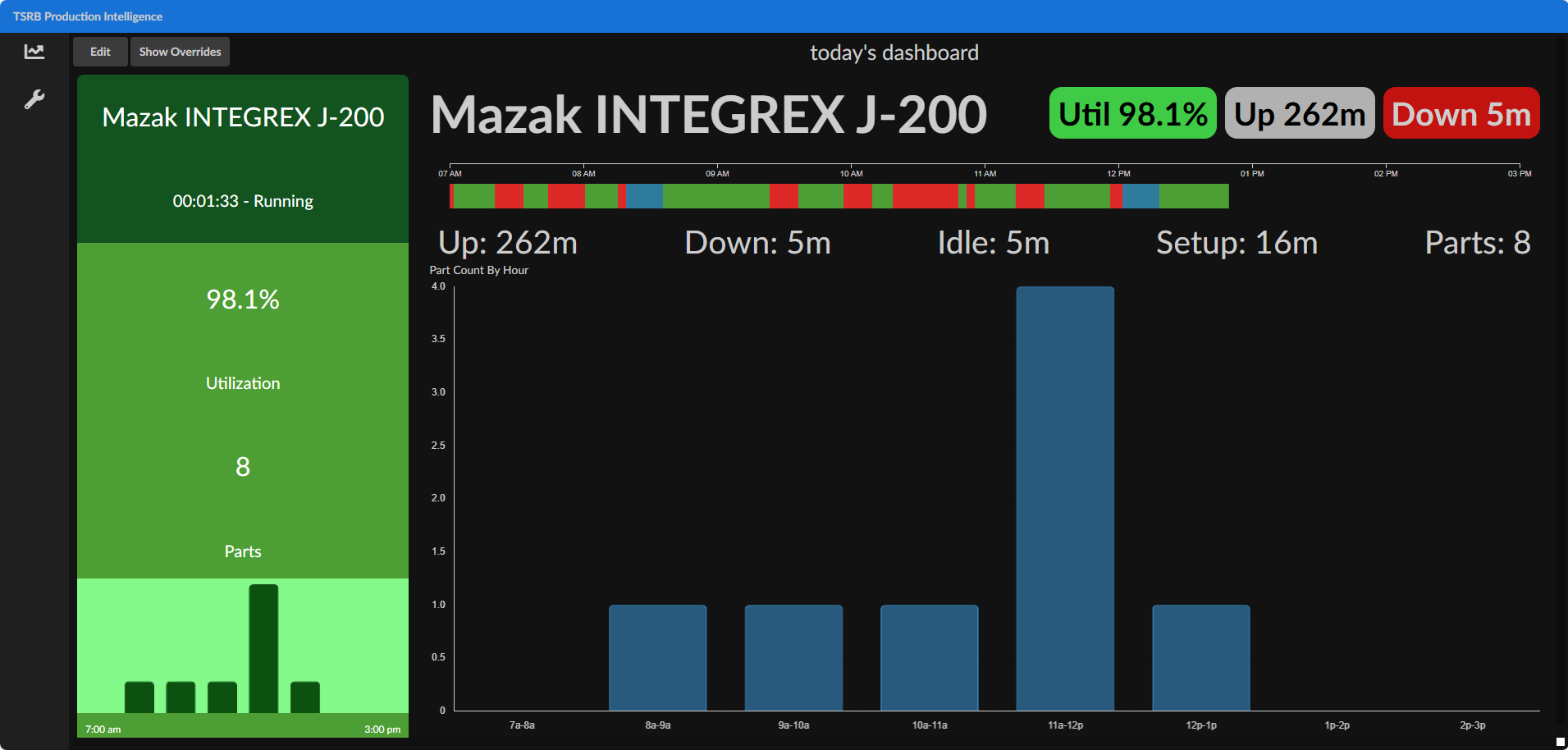

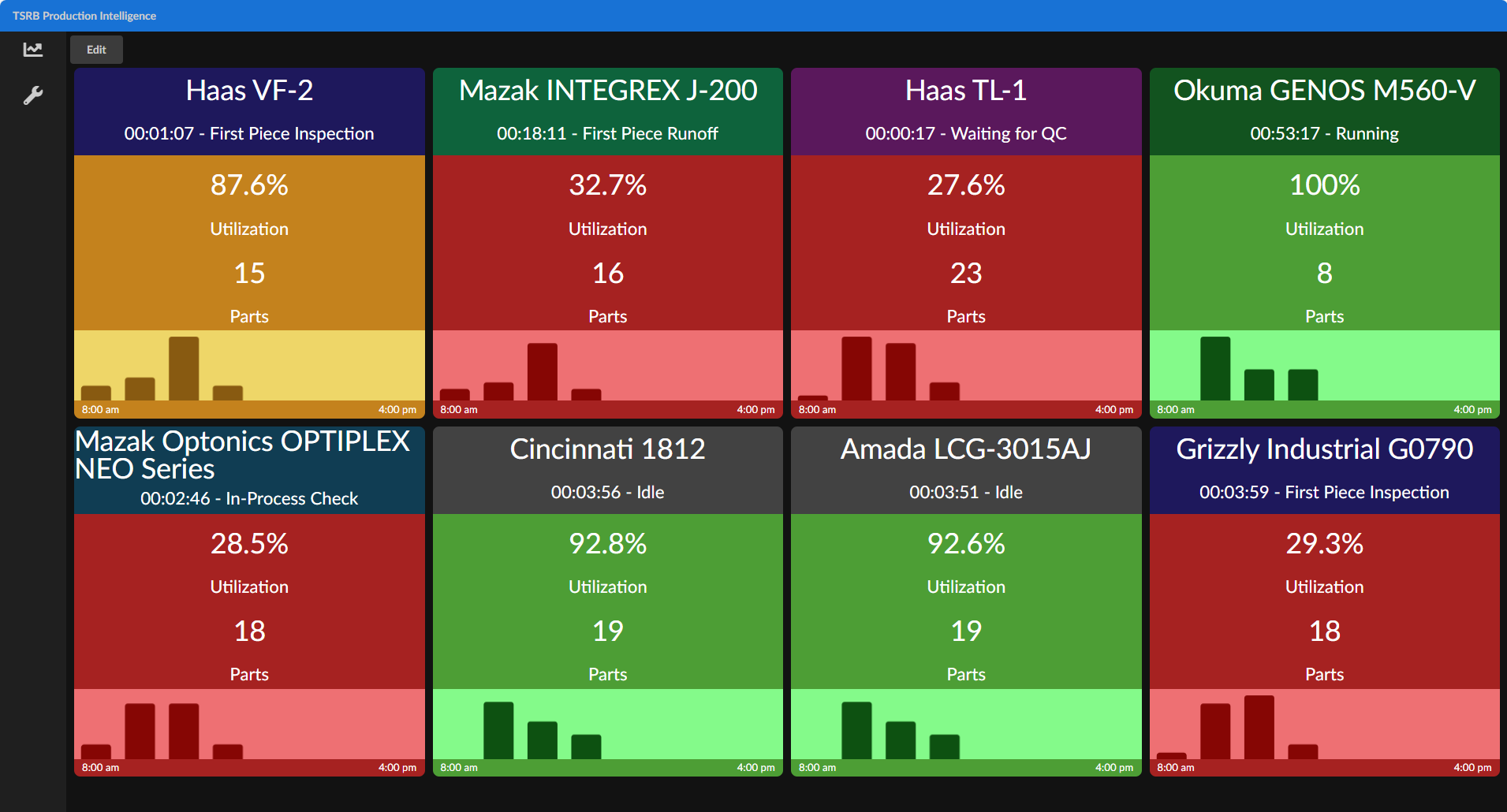

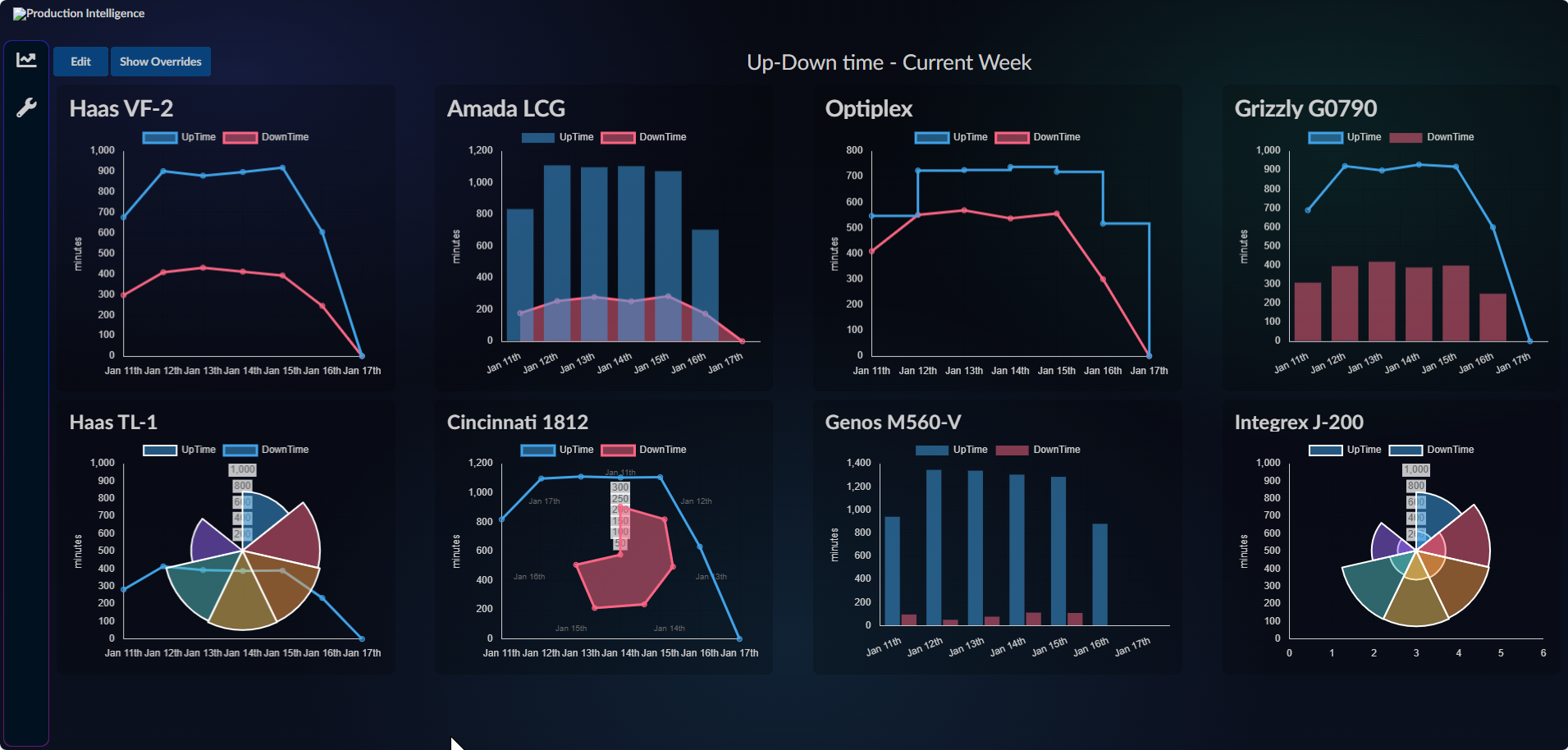

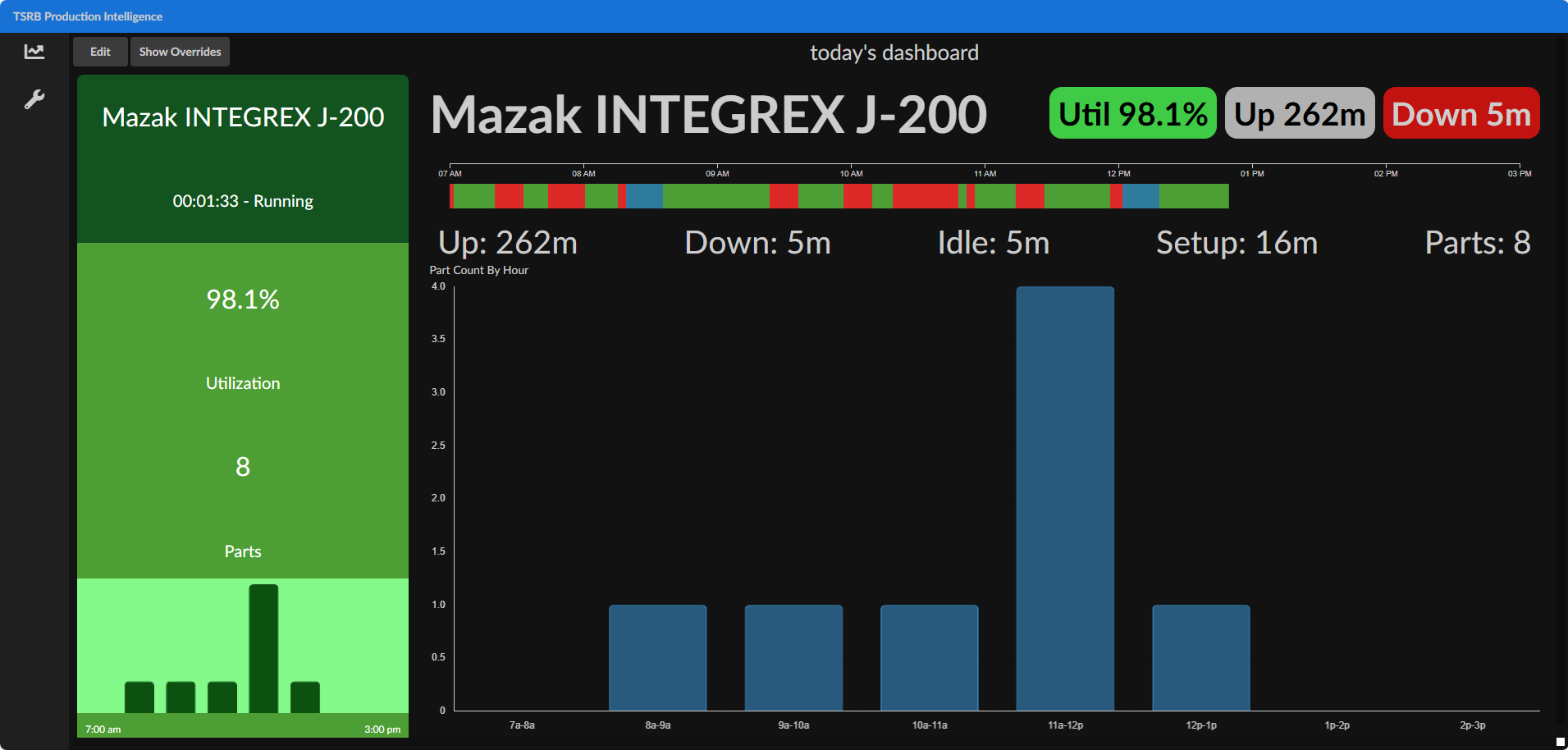

Real-time machine truth

State, utilization, run/idle/down/setup, parts counts, and shift timeline context—at a glance.

Timeline & micro-losses

See exactly when the shift bled time—minute-level segments you can investigate and fix.

SLA clocks & escalation

When it’s not handled, it escalates. When it’s handled, it’s timestamped and attributable.

Hard gates & holds

Quality holds are real. Safety restart requires verification. Readiness gates prevent premature dispatch.

Learning loop

Recurring failures become governed updates to standards—control plans, work instructions, routings, and checks.

Proof of execution

Closure requires evidence—data, photo, verification, sign-off—built for audits and repeatability.

Dashboards

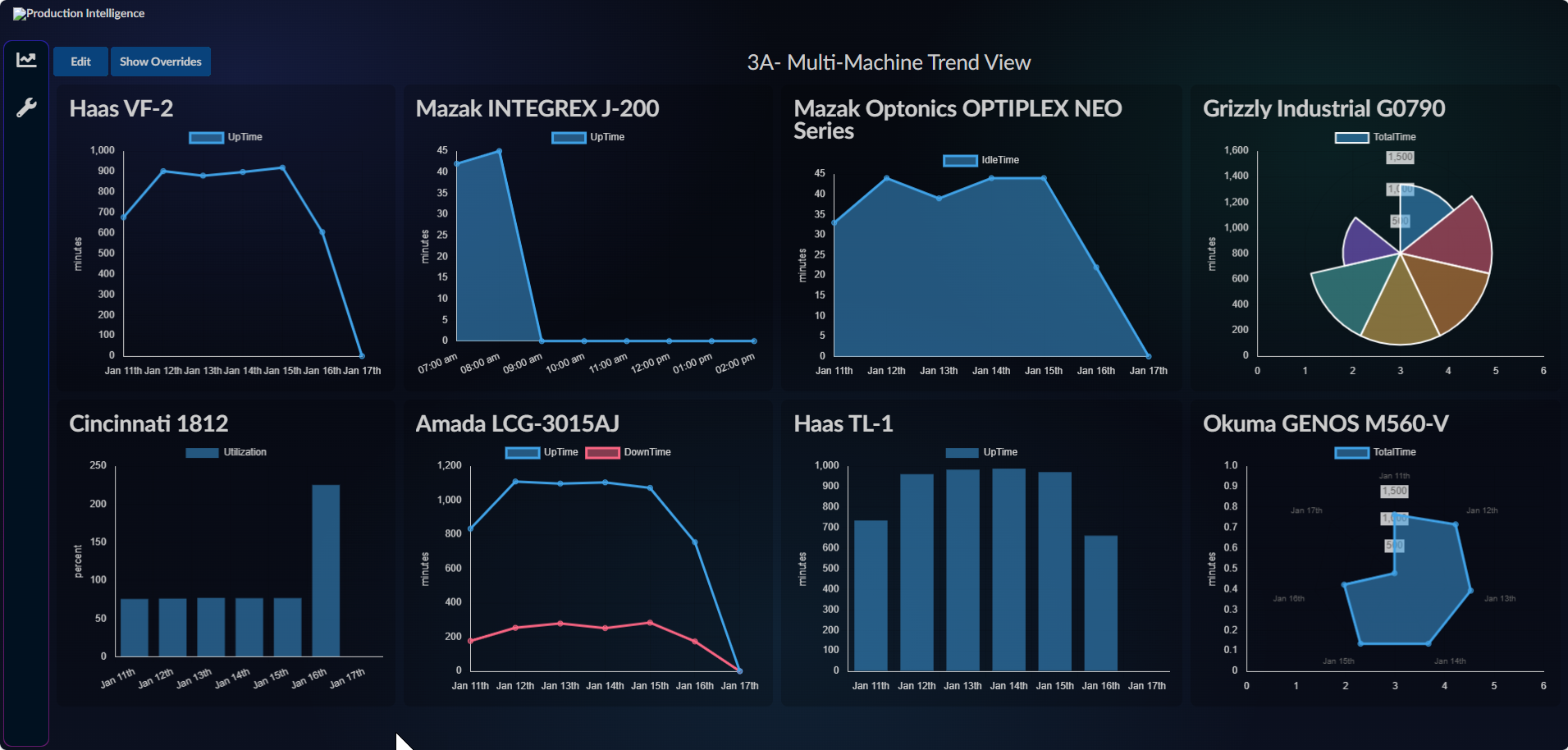

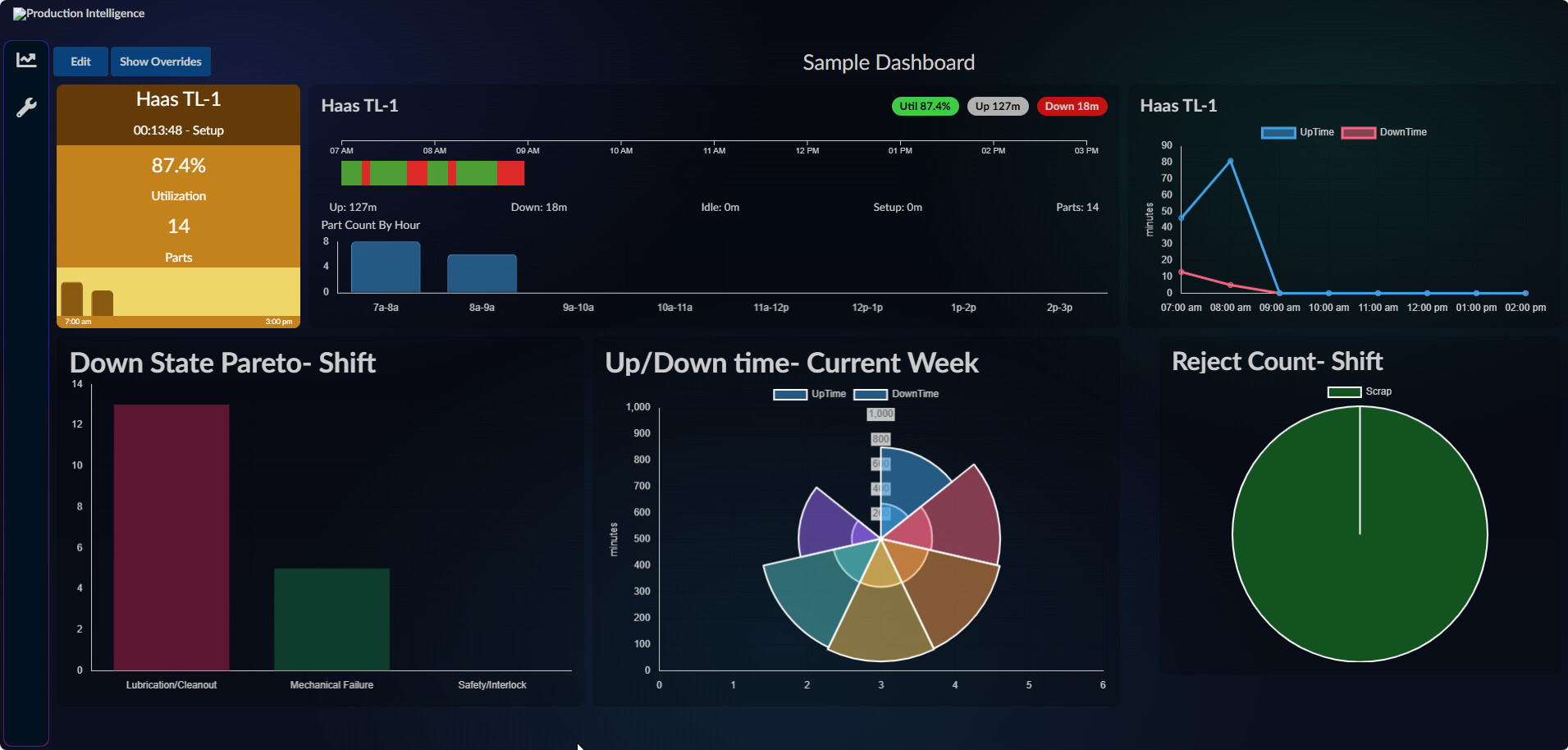

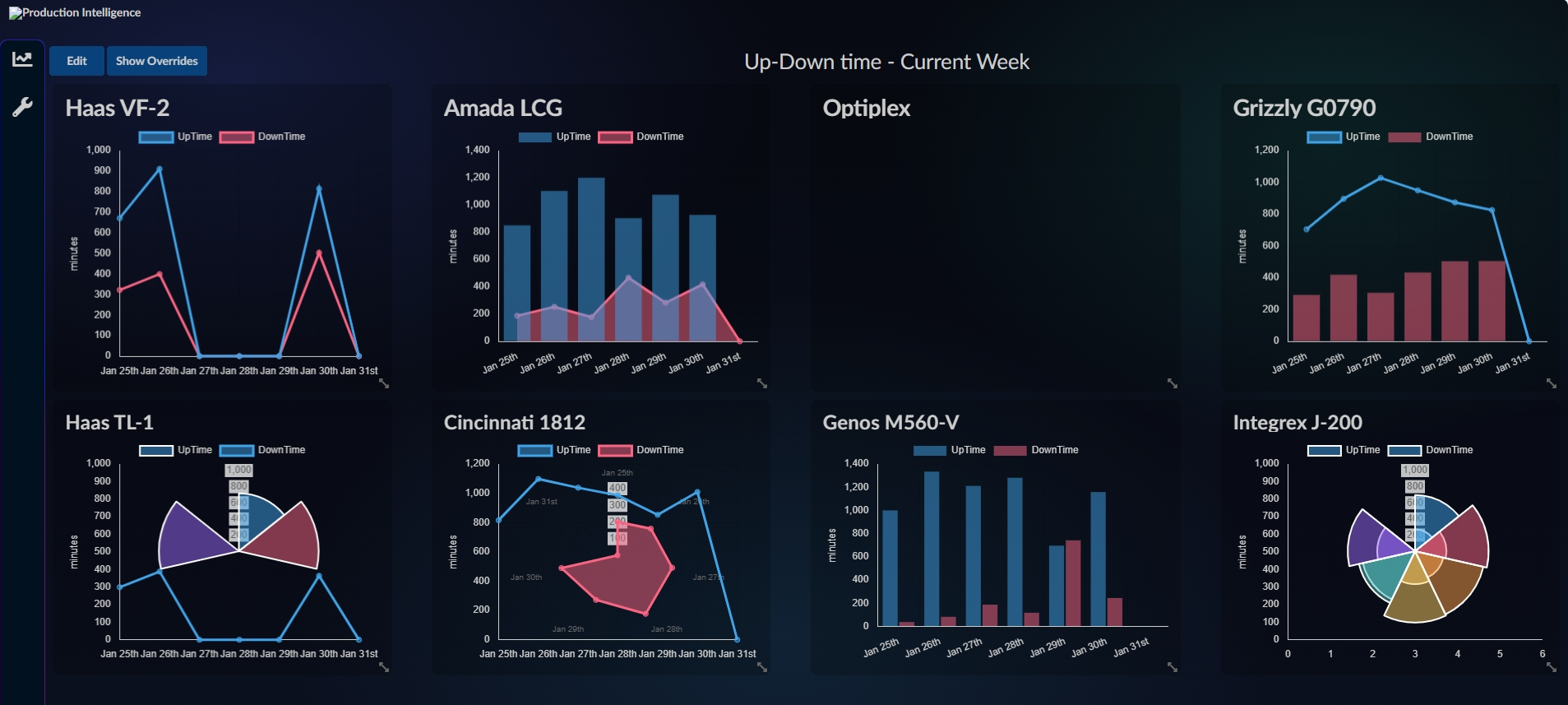

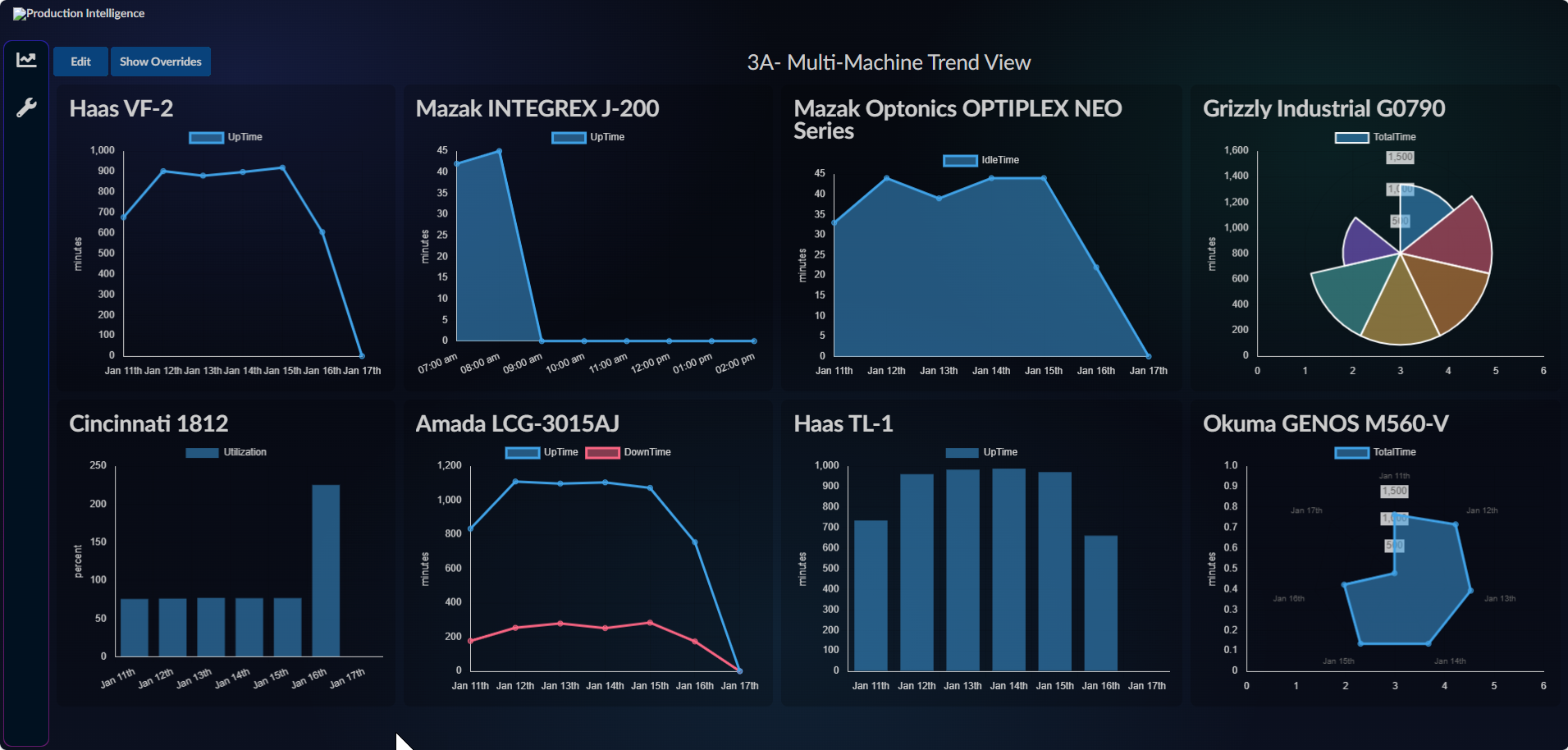

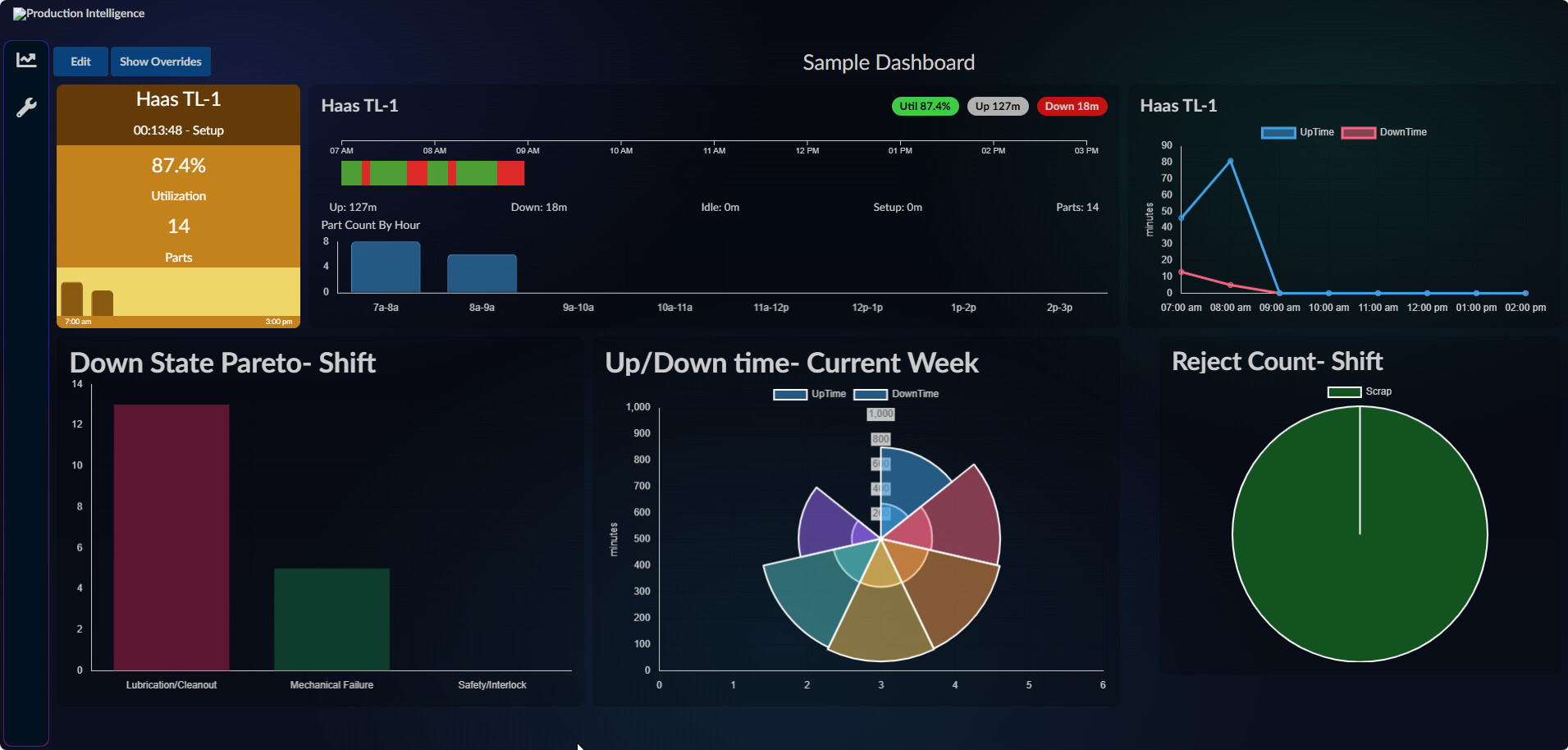

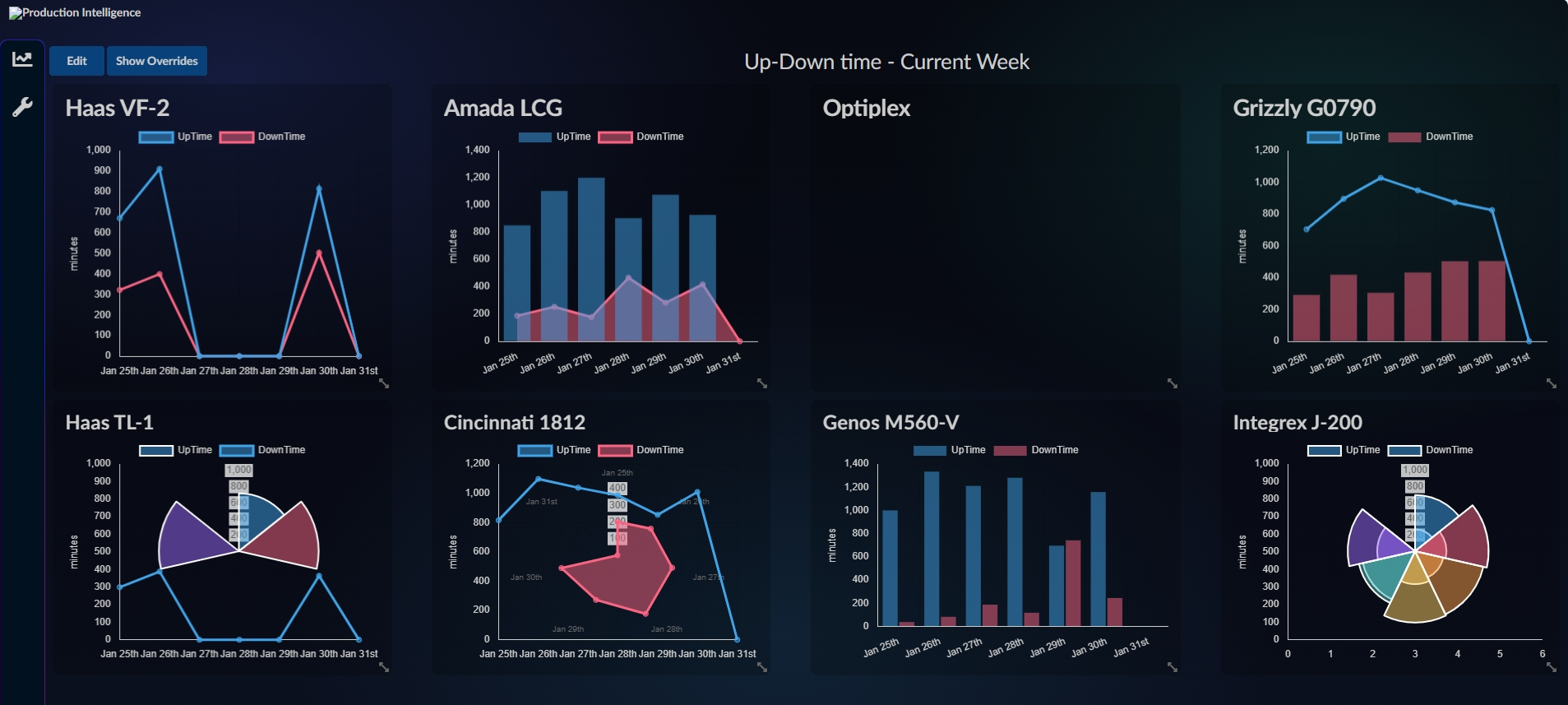

Built for big screens, supervisors, and deep dives

From tile boards that show “what’s happening now” to timeline forensics and weekly trend analysis—TSRB PI scales from quick awareness to root-cause investigation, without losing traceability.

What you see in seconds

Which assets are running, waiting, down, or in a gated state—and how long they’ve been there. Utilization and parts tell you where the shift is headed before it’s too late.

What you prove in minutes

Drill into timeline segments, reasons, and actions. Close with evidence. Capture who acted, when, how, and what changed—ready for ISO / customer audits.

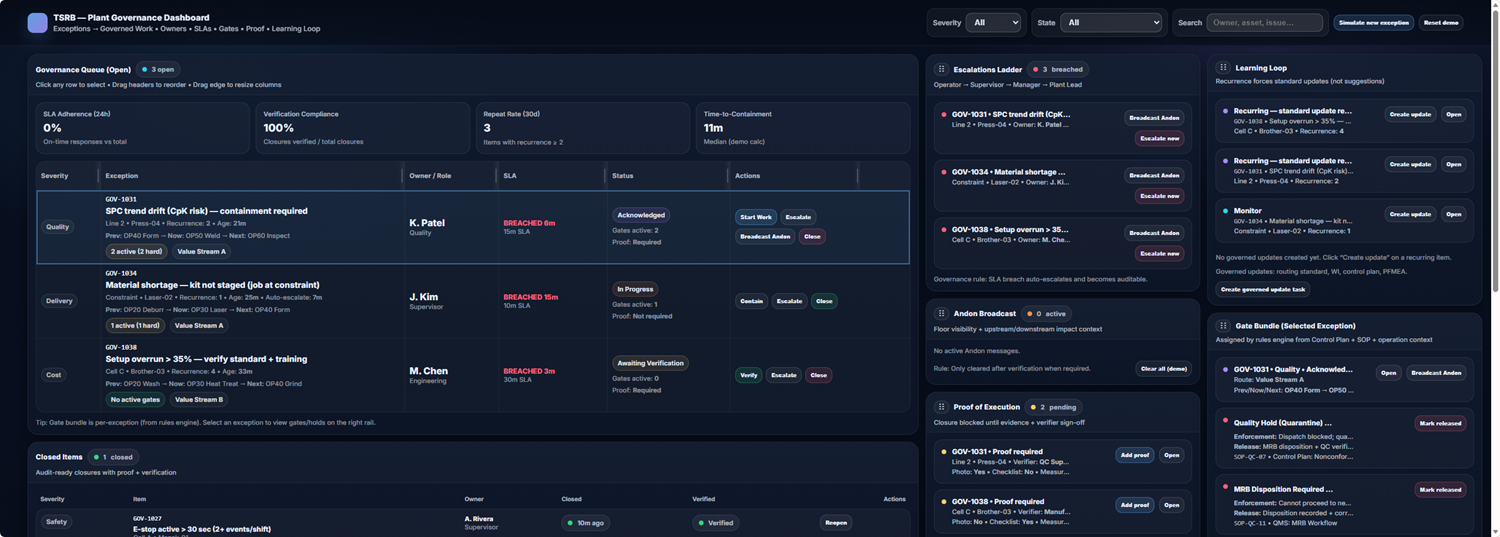

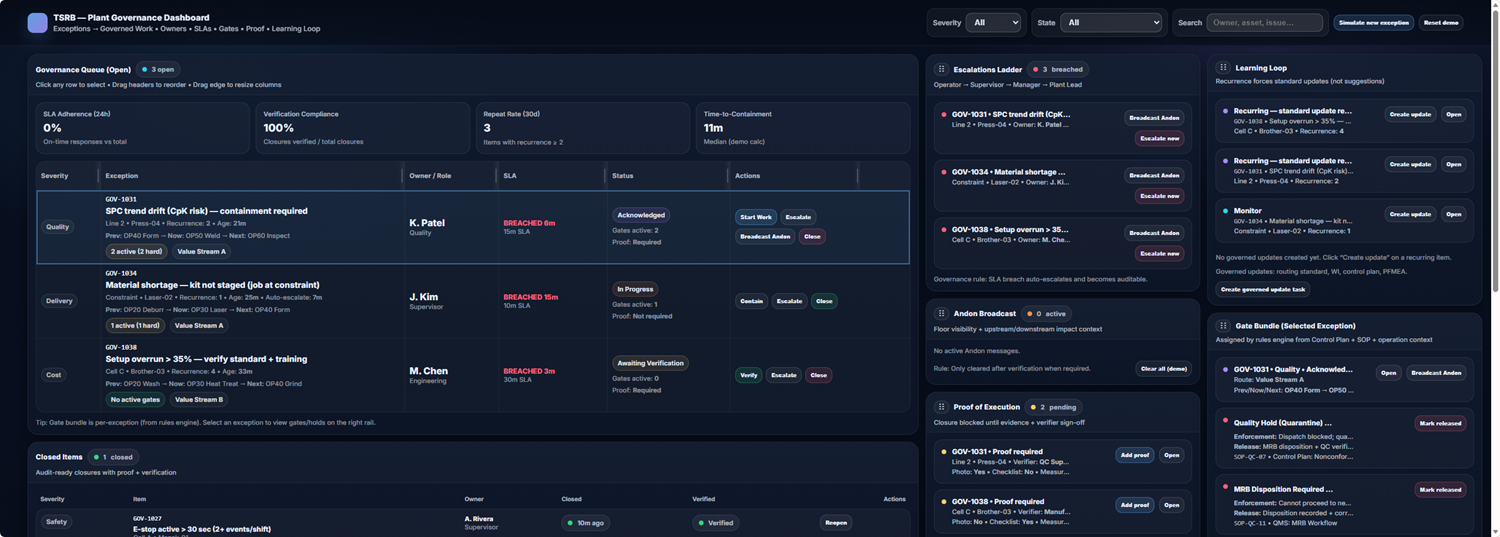

Governance

Convert exceptions into governed work

Alarms are not governance. Governance means: owner assigned, response time enforced, role-specific action sets, escalation when ignored, proof to close, and a learning loop that updates the system so the same failure is less likely tomorrow.

Non-negotiables TSRB enforces

- Ownership & accountability: every exception has an owner and a role context.

- Time enforcement: SLA clocks measure response, containment, verification, and closure.

- Escalation ladder: operator → supervisor → manager → plant lead (configurable).

- Gates that prevent bad outcomes: ship / move / restart cannot proceed until cleared.

- Proof of execution: evidence, verification, and sign-off—auditable by design.

- Learning loop: recurring defects become governed updates to standards and controls.

Governance dashboard example

A governed queue for exceptions, escalations, proof requirements, and learning-loop updates—organized around a repeatable pattern.

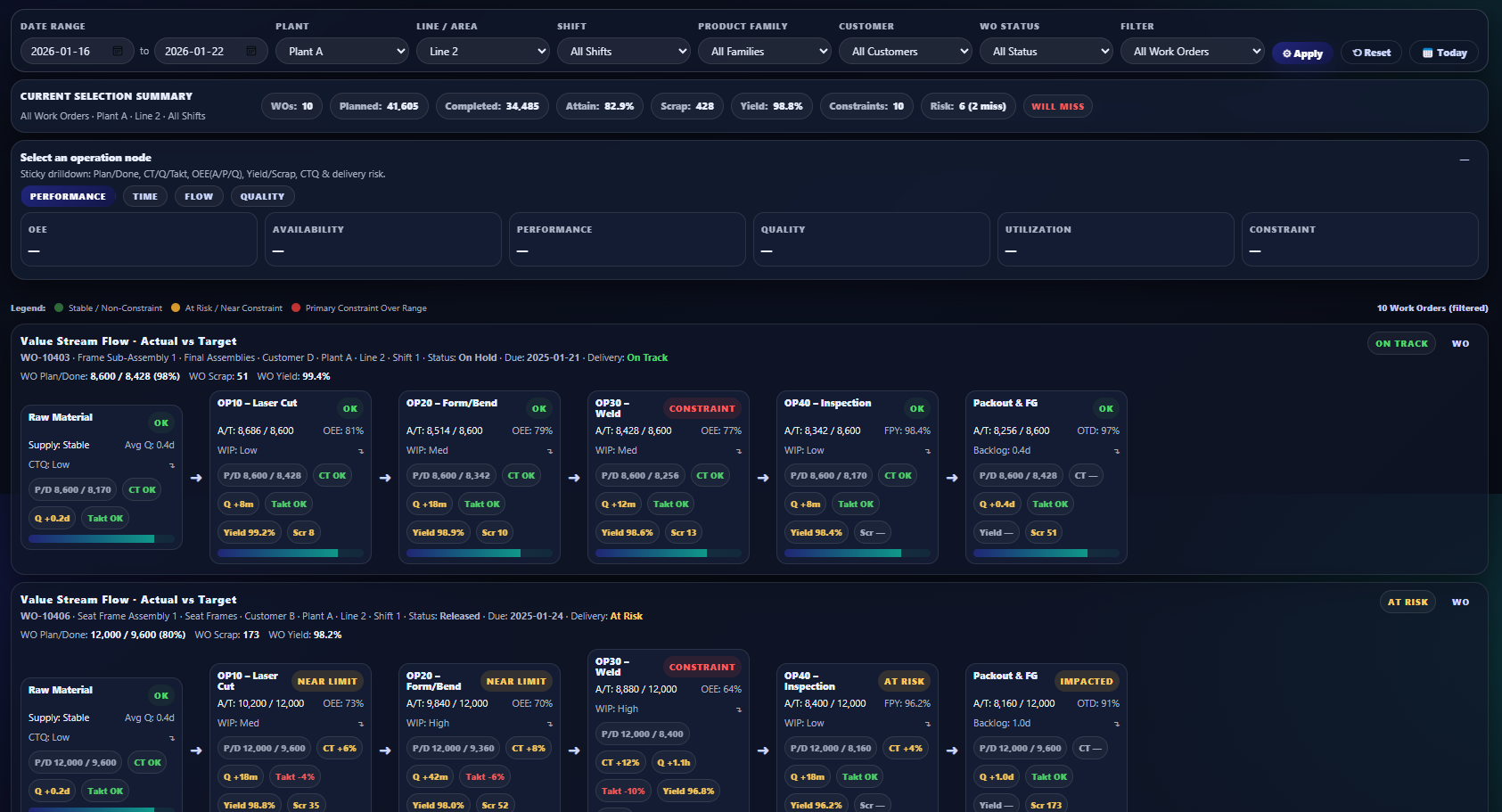

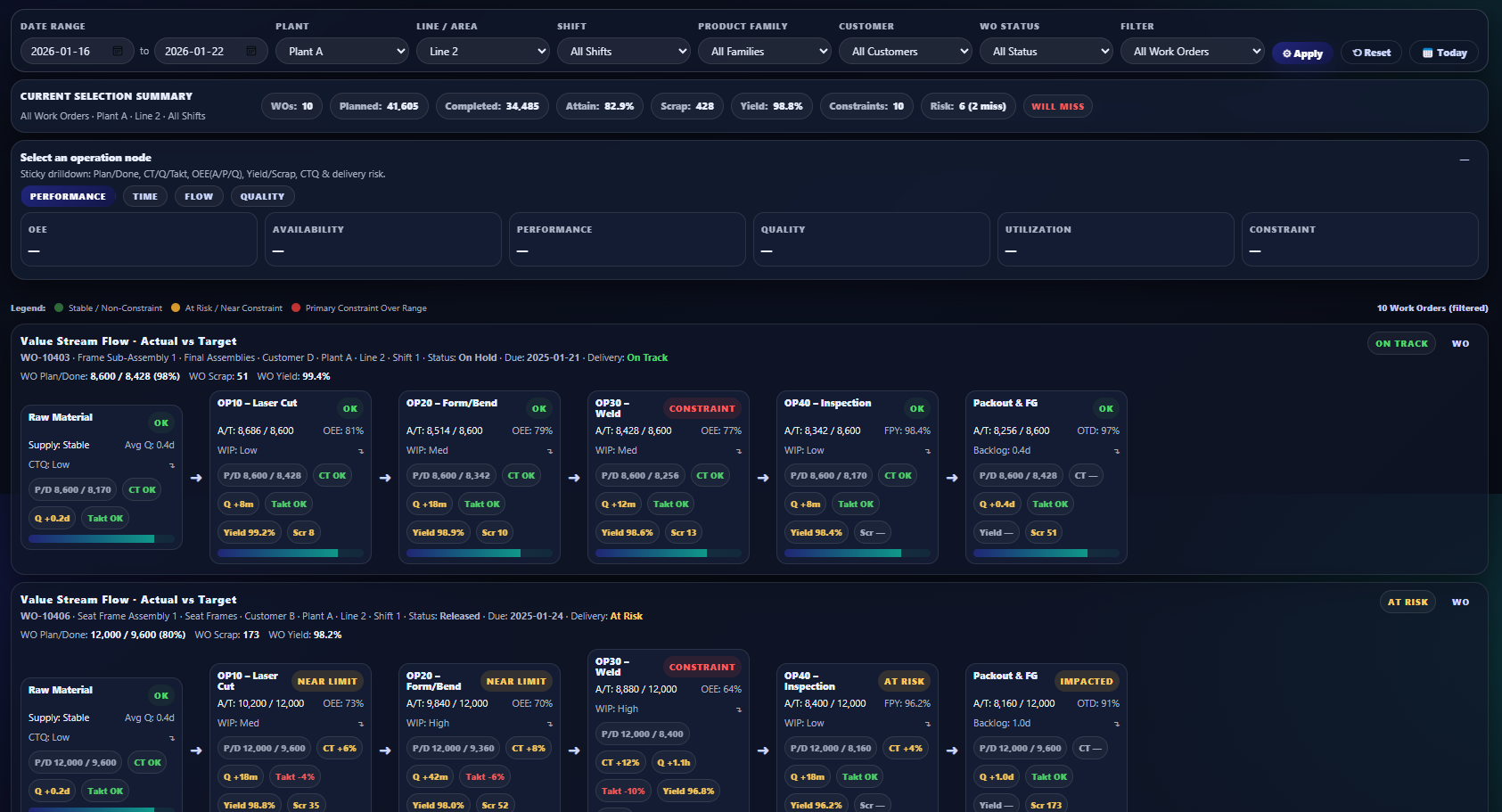

Flow & routing

Protect the constraint and manage the value stream

TSRB PI connects the shop-floor truth to the route: upstream/downstream visibility, operation readiness, WIP risk, constraint protection, and delivery risk—so you can intervene early.

What changes day-to-day

Readiness failures, material staging, inspection queues, and rework loops—surfaced where they impact the constraint and ship date.

What changes permanently

When the routing standard or control plan is wrong, TSRB turns it into a governed update—not a suggestion.

Technology

Modern stack. Industrial reliability.

Production Intelligence is engineered for secure, scalable deployments—from single-site installs to multi-plant rollouts—while keeping the UI fast, responsive, and production-ready.

Built for enterprise environments

- Latest .NET runtime and tooling for performance, stability, and long-term support.

- Written in C# for maintainability, strong typing, and clean domain modeling.

- Designed for real-time updates with scalable data pipelines.

- UI patterns optimized for large displays and control-room usage.

Security & auditability by design

- Role-based visibility and actions (operator / supervisor / quality / engineering).

- Timestamped actions, evidence attachments, and verification records.

- Designed for ISO-style audits and customer traceability expectations.

- Configurable policies for gates, holds, and escalation behavior.

Integrations

Connect to the tools you already run

TSRB PI is built to coordinate governed work across systems: notifications, mobile acknowledgements, ERP interaction, and QMS/TPM tools. The goal is simple: when the process says “stop,” the system can stop it.

Machine connectivity

Real-time state and production signals from CNC, lasers, and automated cells (connector approach supports common industrial protocols).

ERP / MES linkage

Bi-directional workflows for labor tickets, inventory interactions, work order status, and traceability touchpoints.

Quality & maintenance ecosystems

Coordinate governed action with QMS control plans, inspection workflows, TPM tasks, and verification steps.

Alerts that drive action

Email/SMS/mobile acknowledgements, escalation ladders, and upstream/downstream visibility—including Andon/big-screen broadcasting.

Next step

Want a demo built around your plant?

We’ll map your exceptions into governed workflows (owner → SLA → gate → proof → learning) and show the dashboards that matter for your leaders and operators.

Tip: bring one troublesome value stream, one chronic downtime cause, and one recurring quality issue.

Know what’s happening.

Prove what was done.

Prevent what can’t happen.

TSRB Production Intelligence is an operational intelligence layer for discrete manufacturing—built to turn machine, quality, and flow signals into real-time visibility and governed execution. It’s not a KPI wallboard. It’s a system that drives action.

Capabilities

Production intelligence that operators can’t ignore

TSRB PI focuses on the moments that decide whether you ship on time: downtime, quality holds, readiness failures, constraint protection, and recovery actions. When something matters, the system makes it visible—and makes it executable.

Real-time machine truth

State, utilization, run/idle/down/setup, parts counts, and shift timeline context—at a glance.

Timeline & micro-losses

See exactly when the shift bled time—minute-level segments you can investigate and fix.

SLA clocks & escalation

When it’s not handled, it escalates. When it’s handled, it’s timestamped and attributable.

Hard gates & holds

Quality holds are real. Safety restart requires verification. Readiness gates prevent premature dispatch.

Learning loop

Recurring failures become governed updates to standards—control plans, work instructions, routings, and checks.

Proof of execution

Closure requires evidence—data, photo, verification, sign-off—built for audits and repeatability.

Dashboards

Built for big screens, supervisors, and deep dives

From tile boards that show “what’s happening now” to timeline forensics and weekly trend analysis—TSRB PI scales from quick awareness to root-cause investigation, without losing traceability.

What you see in seconds

Which assets are running, waiting, down, or in a gated state—and how long they’ve been there. Utilization and parts tell you where the shift is headed before it’s too late.

What you prove in minutes

Drill into timeline segments, reasons, and actions. Close with evidence. Capture who acted, when, how, and what changed—ready for ISO / customer audits.

Governance

Convert exceptions into governed work

Alarms are not governance. Governance means: owner assigned, response time enforced, role-specific action sets, escalation when ignored, proof to close, and a learning loop that updates the system so the same failure is less likely tomorrow.

Non-negotiables TSRB enforces

- Ownership & accountability: every exception has an owner and a role context.

- Time enforcement: SLA clocks measure response, containment, verification, and closure.

- Escalation ladder: operator → supervisor → manager → plant lead (configurable).

- Gates that prevent bad outcomes: ship / move / restart cannot proceed until cleared.

- Proof of execution: evidence, verification, and sign-off—auditable by design.

- Learning loop: recurring defects become governed updates to standards and controls.

Governance dashboard example

A governed queue for exceptions, escalations, proof requirements, and learning-loop updates—organized around a repeatable pattern.

Flow & routing

Protect the constraint and manage the value stream

TSRB PI connects the shop-floor truth to the route: upstream/downstream visibility, operation readiness, WIP risk, constraint protection, and delivery risk—so you can intervene early.

What changes day-to-day

Readiness failures, material staging, inspection queues, and rework loops—surfaced where they impact the constraint and ship date.

What changes permanently

When the routing standard or control plan is wrong, TSRB turns it into a governed update—not a suggestion.

Technology

Modern stack. Industrial reliability.

Production Intelligence is engineered for secure, scalable deployments—from single-site installs to multi-plant rollouts—while keeping the UI fast, responsive, and production-ready.

Built for enterprise environments

- Latest .NET runtime and tooling for performance, stability, and long-term support.

- Written in C# for maintainability, strong typing, and clean domain modeling.

- Designed for real-time updates with scalable data pipelines.

- UI patterns optimized for large displays and control-room usage.

Security & auditability by design

- Role-based visibility and actions (operator / supervisor / quality / engineering).

- Timestamped actions, evidence attachments, and verification records.

- Designed for ISO-style audits and customer traceability expectations.

- Configurable policies for gates, holds, and escalation behavior.

Integrations

Connect to the tools you already run

TSRB PI is built to coordinate governed work across systems: notifications, mobile acknowledgements, ERP interaction, and QMS/TPM tools. The goal is simple: when the process says “stop,” the system can stop it.

Machine connectivity

Real-time state and production signals from CNC, lasers, and automated cells (connector approach supports common industrial protocols).

ERP / MES linkage

Bi-directional workflows for labor tickets, inventory interactions, work order status, and traceability touchpoints.

Quality & maintenance ecosystems

Coordinate governed action with QMS control plans, inspection workflows, TPM tasks, and verification steps.

Alerts that drive action

Email/SMS/mobile acknowledgements, escalation ladders, and upstream/downstream visibility—including Andon/big-screen broadcasting.

Next step

Want a demo built around your plant?

We’ll map your exceptions into governed workflows (owner → SLA → gate → proof → learning) and show the dashboards that matter for your leaders and operators.

Tip: bring one troublesome value stream, one chronic downtime cause, and one recurring quality issue.